CAPABILITIES

Our Services

our capabilities

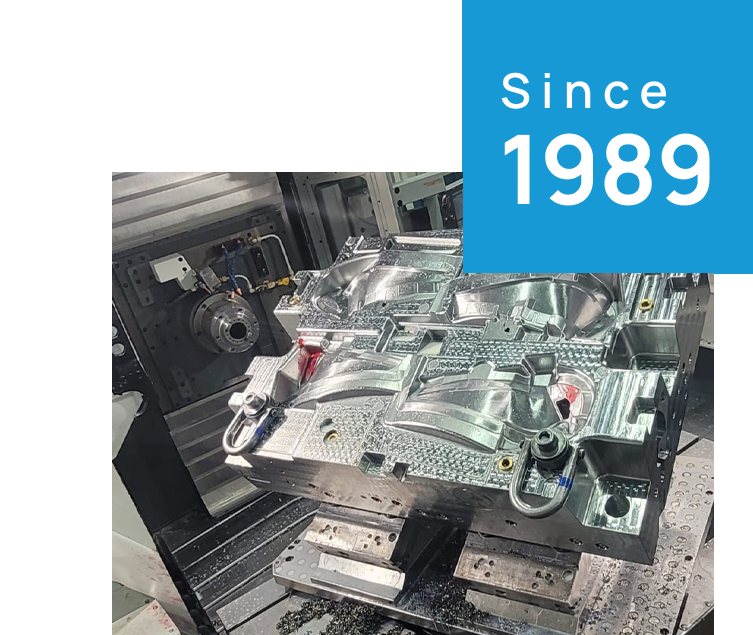

Step into the world of precision with WinTex Tooling Technologies.

At WinTex Tooling Technologies, we offer comprehensive manufacturing solutions tailored to your needs. From CNC machining with multi-axis capabilities to high-speed Graphite machining, we deliver complex precision with ease. Experience our expertise in mold making, 2-shot mold making, deep hole Gundrilling, product development and design and structured engineering.

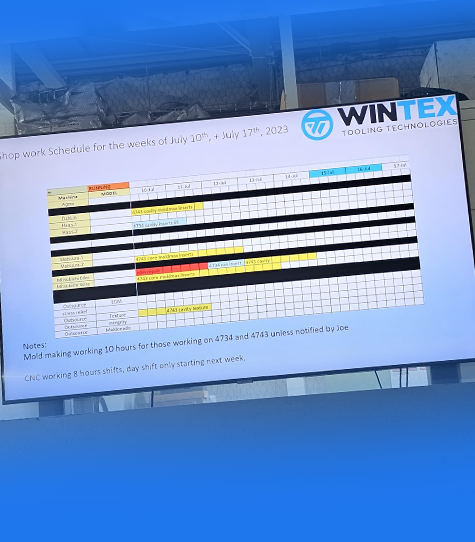

Program Management

Single point of contact

At Wintex, our skilled Program Managers act as the single point of contact for all projects, including new core designs, builds, and engineering changes. With expertise in overseeing various tooling types, they effectively track and manage the entire tool build process from design to T1, attending tryouts at customer facilities to ensure seamless execution.

CAPABILITIES

Operational Support

Seamless project oversight from design to T1 with experienced program managers for on-time delivery.

Dedicated Management

Single point of contact for new core designs, engineering changes, and effective communication with the shop.

Expert Analysis

Collaborative engineering partnership with Product Design Solutions (PDS) for flawless mold flows.

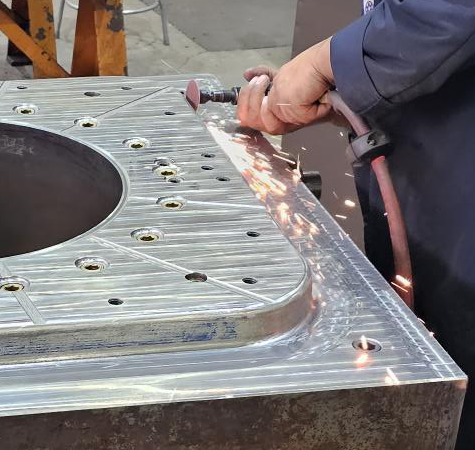

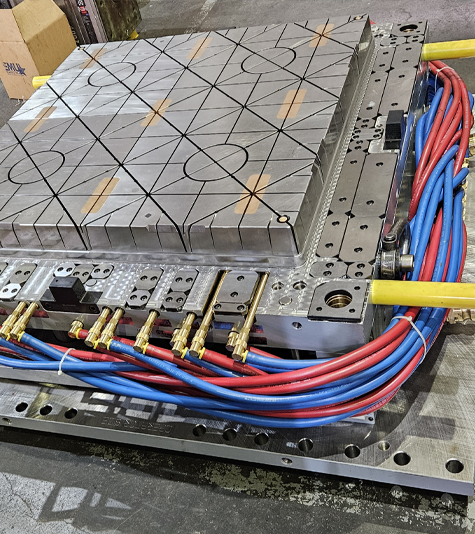

Mold Making

Comprehensive Solutions

At Wintex, our Mold Making services excel with an experienced team supported by our high-end machining department. We take pride in delivering top-notch tool repair and support, including hot runner system installation and repair, CMM capabilities, and reverse engineering.

Our 24-hour emergency in-house service and micro welding expertise address urgent requirements. With skilled toolmakers dedicated to the highest quality, we achieve zero parting line tolerance. Our expertise extends to rotary tools, two-shot tools, lens, and quality tools, ensuring precision and reliability in every tool repair.

CAPABILITIES

Innovation

Embrace innovation with advanced 3D and 2D programming, alongside high-speed Graphite machining using System 3R

Versatility

Unleash versatility and accuracy with our CNC Wire EDM and EDM sinker services for all machining needs.

Complexity

Master complexity with extensive multi-axis machining capabilities, delivering precision results.

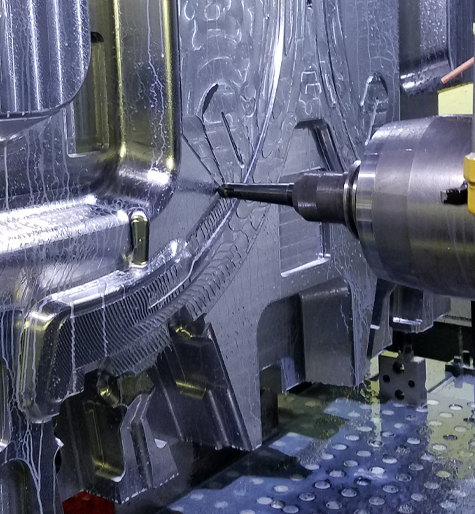

CNC Machining

Cutting - Edge

At Wintex, our CNC Machining service is led by experienced professionals with 35+ years of expertise. Powered by cutting-edge 3D and 2D programming software, we deliver outstanding results. We excel in high-speed Graphite machining, hardened component machining, and deep hole Gundrilling (up to 28 inches deep).

Our multi-axis machining, CNC Wire EDM, and CNC EDM sinker capabilities ensure precision and versatility. With advanced CNC machines, including Matsuura, Dahlih, Haas, Agma, Mitsubishi, and Makino, we take great pride in delivering timely solutions and maintaining competitive pricing.

CNC Machines:

Matsuura #1 FX-5G / X 40in. / Y22in. / Z21.5in. / 1300lbs.

Matsuura #2 FX-5G / X 40in. / Y22in. / Z21.5in. / 1300lbs.

Dahlih MCV-1450 / X 62in. / Y31in. / Z29.5in. / 4400lbs.

Haas#1 EC1600yzt / X 64in. / Y50in. / Z32in. / 10,000lbs.

Haas#2 EC1600 zt / X 64in. / Y50in. / Z32in. / 10,000lbs.

Agma VMC-158 / X 51in. / Y29.5in. / Z28in. / 4400lbs.

Mitsubishi EDM EX30 / X48in. / Y32in. / Z23in. / 5000lbs.

Makino Wire EDM SP64 / X46in. / Y16in. / Z16in. / 1300lbs.

CAPABILITIES

Advanced Machining

Deep hole Gundrilling up to 28 inches, demonstrating advanced machining techniques.

Efficiency

High-speed machining of hardened materials, ensuring top-notch quality and efficiency.

Accuracy

CNC Wire EDM and EDM sinker services for versatile and accurate machining solutions.

Engineering

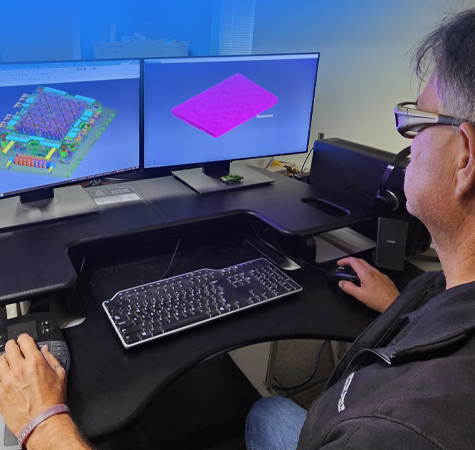

Innovative Solutions

Wintex is dedicated to innovative solutions and provides advanced engineering services. Our in-house team employs Siemens NX customized software, enabling our team to deliver advanced custom engineering solutions. With expertise in surface molding, advanced engineering, and reverse engineering for effective repairs and adjustments, we deliver exceptional results.

Our standardized component and assembly system, combined with collaboration with Product Design Solutions (PDS) for mold flows, guarantees top-tier project outcomes. Count on our skilled and knowledgeable team for all your needs.

CAPABILITIES

Engineering

Comprehensive engineering support with advanced Siemens NX software for innovative solutions.

Design

Innovative designers and surface molders, ensuring creative and efficient product development.

Analysis

Feasibility analysis and reverse engineering capabilities for seamless mold repairs and changes.

Maintenance and Repair Work

Service on demand

Wintex’s Maintenance and Repair Work services are backed by an experienced team, ensuring high-quality tooling fixes. We offer 24-hour emergency in-house service, supported by our high-end machining department for seamless repairs.

Our capabilities include micro welding and heat treating to meet your unique requirements. Count on us to provide comprehensive support for hot runner system installation and repair, with CMM capabilities for precision. Your tools are in capable hands, and we take pride in delivering the best results.

CAPABILITIES

In-House Support

24-hour in-house emergency service for rapid response and minimized downtime.

Precision Repair

Micro welding capabilities for precise and intricate repairs on molds and components.

Quality Assurance

CMM capabilities for accurate and thorough inspections and quality assurance.

Product Design Development

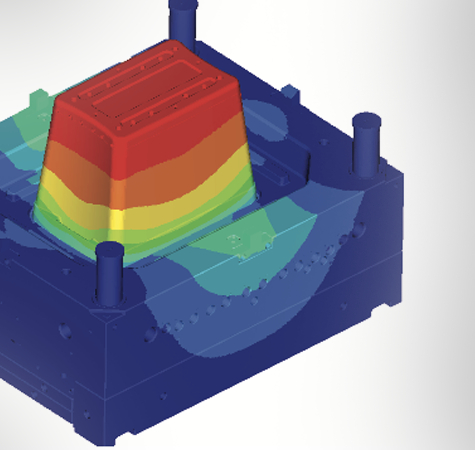

Moldflow and FEA

WinTex has partnered with Productive Design Services (PDS) to provide cutting-edge techniques for complex applications. PDS is our preferred source for Moldflow’s and FEA’s. Through this partnership, we harness the capabilities of Moldflow services to excel in the field of plastic injection molding. By combining reverse engineering services with Moldflow simulation, we offer effective solutions for reducing warp, saving time, and cutting costs associated with warp-prone parts.

Our commitment to excellence is reflected in our certified expert analysis, ensuring the delivery of high-quality parts and complete customer satisfaction throughout the prototype to the production phase.

CAPABILITIES

Finite Element Analysis (FEA)

WinTex collaborates with PDS to deliver a comprehensive suite of finite element analysis (FEA) services. Our goal is to address complex challenges and assist you in optimizing the design of your injection molded parts, achieving maximum performance while reducing costs.

Moldflow Services

WinTex partners with PDS and uses cutting-edge software to conduct injection molding simulations during the initial stages of design. This enables us to identify potential design challenges before making investments in dedicated tooling, saving you valuable time and resources.

Comprehensive Product Design Services

Our extensive range of services includes local warp reversal, shrinkage compensation-based warp reduction, total part warp reversal, reverse engineering from Moldflow analysis, reverse engineering from point cloud scans, and windage verification using Moldflow analysis.